Third-Party Inspection Company Explained

The first-party inspection involves the manufacturing house self-assessing the product’s quality. The second-party inspection is undertaken by the buyer or the buyer’s in-house quality examination team. Third-party checks are performed by an independent company to verify the quality claims. The third-party inspection contractors are generally hired by the buyers to ensure that the product specifications match its standards. Buyers utilize autonomous inspection service providers to validate that the manufacturing process meets international standards in terms of the quality management system, environmental management, and corporate social responsibility. Since they provide an impartial perspective on the quality of the goods, most companies find hiring a third-party inspector a justifiable expense.

Independent and Impartial Analysis

Third-Party Inspection (TPI) is the assessment and the inspection of services conducted by a 3rd party quality company. The purpose of getting the product or service examined by a third is to ensure the compliance of purchased products or services to the international code of standard, customer specifications, and environmental norms. The process involves inspection during and after the product’s manufacturing or the rendering of the said service. A third-party inspection company in India or Asia usually provides the following services.

- Technical control and support

- Testing and inspection

- Unbiased scrutiny

- Approval services

A third-party inspection company provides around-the-clock assessment services to its clients. The inspections performed by third parties are certified. A TPI enterprise team is experienced, well-trained, and specialized in either a few or multiple product categories.

Benefits of Availing the Services of a Third Party Contractor

Importers and business organizations can gain the following advantages if they employ the services of a third-party Inspection Service Provider.

- Effortless communication: The client manager provided by a third-party quality control company is less likely to misunderstand the expectations prescribed by importers. Individuals appreciate the presence of a reliable figure that can comprehend the standard specifications and implore the suppliers to deliver the right product.

- Cost-effective and efficient: TPI is more commercial than alternate modes of inspection since self-examination can require travel abroad to gauge the quality of the product. However, 3rd party quality companies have local experts stationed at various locations to assist their clients with standard testing. It improves operational efficiency and guarantees certified product delivery.

- Better consumer relations: The relationship between a supplier and an importer is based on the thread of trust. The importer keeps faith in the supplier for the delivery of quality goods while the seller cannot receive any feedback until the buyer sees the product and reviews it. The time lag and miscommunication can turn the relationship sour. Therefore, a third-party contractor acts as a mediator and improves consumer relations by giving unbiased feedback.

- Preventing a disparity between expectations: The level of transparency is limited between a supplier and an importer. TPI eliminates the problems by placing your expectations upfront before the commencement of the production process. By employing a third-party supervisor, a supplier can exert a guarantee under the following situations.

- a. Verify with the customer the actual terms of the contract and exhibit the condition and status of the production process.

- b. Gather immediate feedback from the buyer related to non-conformity or violation of any code standard or specifications.

- c. Foster a relationship based on faith and trust.

The inspectors will ensure that the factors mentioned above are carefully examined, and the verification is undertaken most professionally.

- Avoiding order withdrawal: Suppliers and buyers prevent the shipment of substandard goods since it induces inconvenience on both sides. Importers will not tolerate a consignment of products with defective pieces because it hurts their supply chain and relationship with the clients. Therefore, they often tend to charge the suppliers heftily for faulty items exceeding the prescribed number. Third-party inspection companies assist suppliers in mitigating losses on the grounds of product rejection.

Re-iteration of these aspects is significant to establish the vitality of 3rd party quality control companies. Importers and suppliers must build a chain of trust. However, the uninterrupted delivery of superior quality products is guaranteed by independent contractors who try to make ends meet and assist their clients by working around the clock.

When to Hire a Third Party Inspection Company

There can be several instances when companies require the services of a third-party inspector. Business owners continuously face a dilemma as they struggle to outsource inspection to a random company. However, we have enlisted the situations where your company will require the assistance of a 3rd party inspection company.

- Enterprises must employ the services of a third-party inspection organization when working with new suppliers. The experts retained by the company are well-versed in multiple product categories. Evaluating the acceptable standards of the product offered by a new supplier will be an easy task.

- If your in-house quality verification team is falling short on the benchmark results, you need a third-party inspection company to remove the inefficiency.

- If your enterprise purchases premium items, including high-end electronics or industrial equipment, you will need hands-on experts in your corner to examine the quality and technical specifications of the goods delivered.

- Experts advise that it is better to assess the goods at different stages during production than to solve the issues with the supplier when the product is already shipped. It is less costly and convenient on both ends. Repeated product quality issues reflect flaws in the production chain, which require immediate rectification and the unbiased eye of a third-party inspector.

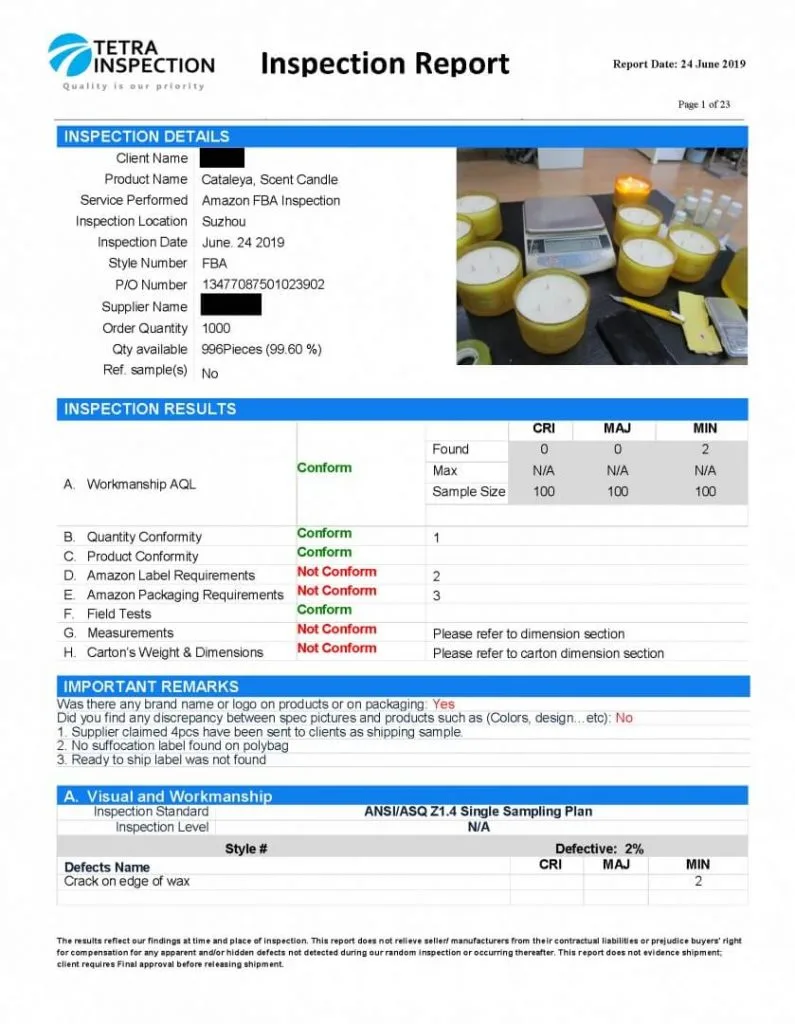

Business owners must realize that it is less costly to employ an autonomous third-party contractor than to have the entire shipment of goods revoked. Independent quality inspectors examine the product with a bird’s eye view and provide a completely impartial evaluation. Since they are familiar with the technical specifications of multiple product categories, proprietors must put pre shipment inspection companies on retainers. Should there arise the necessity of a third-party quality control inspector, you can contact Tetra Inspection with your requirements.

Tetra Inspection Coverage:

You can use Tetra Inspection services across 40 countries, Tetra Inspection has been nominated as the best 3rd party inspection Pakistan in 2020.

Contact us today for one-stop quality control solutions.

Preventing a disparity between expectations –

so Customized Quality control services. The boy liked birds, but he was afraid of cats. Similarly, he did not like lions and tigers. Jonas promised to love, honor, and also obey his wife. Moreover, he will do all the cooking and cleaning while he studies at home. Furthermore, he is grateful that his new wife earns enough money to pay the bills.

Harry ate six shrimp at dinner. Beautiful giraffes roam the savannah. Sue changed the flat tire. We are going to watch a movie tonight. I will clean the house every Saturday. so, Tom painted the entire house. The teacher always answers the students’ questions. Harry ate six shrimp at dinner. Beautiful giraffes roam the savannah. Sue changed the flat tire. We are going to watch a movie tonight. Mom read the novel in one day. I will clean the house every Saturday. Tom painted the entire house. The wedding planner is making all the reservations. The director will give you instructions. Ali is fat. saim is slim. Tahir is clever. Mom cooks food. I do Amazon FBA Inspection. Ali is bad. I go to school. Finally, I left my job. Eventually, I have passed the test. life is easy. And he does it. So he plays cricket. Tabi is bad.