Adhering to quality control best practices in manufacturing delivers high-quality products, which sell out quicker than defective products.

Product Inspection in China | Quality Control in China

A leading 3rd party inspection company in Vietnam and Asia.

Product Inspection in China

Performing Product Inspection in China works as a safeguard for buyer, manufacturer and customers as it ensures that the product meet required specifications and safety requirements.

In the current highly globalized world, it is next to impossible to talk about manufacturing without mentioning China. The supply chain of most import-export businesses globally has at least one supplier in China. While sourcing manufactured goods from China offers a wide range of benefits, it also comes with a myriad of challenges.

According to global product inspection data, AQL failure rates for China is around 30%, which means that one-third of the products are either defective or non-compliant with custom regulations. But, you can avoid quality issues and mitigate the risks of non-compliance by adhering to QC best practices. Whether you’re a retailer or an importer, quality control in China is important.

What is Quality Control in China?

China’s quality control refers to proactive measures taken by importers and their inspection agencies in China to guarantee product quality. To ensure you import quality products, China’s quality control process is designed to help you partner with the right supplier. Quality inspection services focusing on verifying potential suppliers can avoid scammers and incompetent manufacturers while factory audits can highlight the capabilities of suppliers. Social audits assess the supplier’s ethical conduct like equality in the workplace, environmental issues, and human rights. The audits and inspections used in pre-production lay the foundation of the China QC process but it should be guided by a comprehensive quality control checklist.

Once you find and partner with the right supplier or manufacturer in China, a quality inspection services provider nominated by you will focus on product inspection starting with an initial production check before mass-production. After that, they will proceed to DUPRO and Pre shipment inspection (PSI). Your quality control process in China is completed when the inspection agency supervises the loading of your products for shipping. It is undeniable that adhering to quality control best practices when dealing with suppliers from China offers a wide range of benefits.

Benefits of Quality Control when Importing from China

Whether you are an importer or retailer, China’s quality control can benefit your business in many ways. Here are a few benefits of QC for importers engaging with Chinese suppliers. You can only enjoy all these benefits if your product inspections and supplier audits are undertaken by the right entity.

- Quality Assurance

Being conscious of the quality of your products is vital for success. You can define your product requirements clearly to ensure you attain shipment that sells easily.

- Customer Satisfaction

Quality inspection can help you deliver quality products consistently. This is the priority for you to satisfy your customers.

- Cost Reduction

Quality control in manufacturing can surface defects and non-compliance issues early. You can take corrective action and reduce the cost of reworks.

- Avoid delays

Most countries require an inspection certificate to allow entry of imports. QC can deliver inspection certificates and reports quickly and help you avoid costly delays.

- Preserve Resources

QC delivers batches with products that meet the Acceptable Quality Limit (AQL). Fewer defective products reduce wastage of resources on reworks.

- Increased Sales Margins

- Reduce costly defects

QC allows for pre-production and pre-shipment product inspections in China, which can help you avoid shipments with too many defects.

- Protect your reputation

QC process in China includes ethical audits of potential suppliers to weed out problematic suppliers and protect the reputation of your business.

- Quality Assurance

Being conscious of the quality of your products is vital for success. You can define your product requirements clearly to ensure you attain shipment that sells easily.

- Regulatory compliance

QC allows monitoring of supplier’s factory and operations. It can reveal issues early and allow prompt correction to guarantee compliance.

Who can Undertake Quality Control for Imports from China?

Quality control goes beyond the jurisdiction of one entity. Importers engaged with suppliers from China can delegate their quality control process to one of four entities:

In-house Manufacturer review. Importers award the manufacturer the authority to oversee quality control. It is risky since they will be reporting on their operations.

Buyer QC. As the buyer, you can undertake quality control by visiting the manufacturer yourself or appointing one of your staff members to oversee the entire process.

Supplier or Sourcing Partner. You can assign quality control to your partner or supplier in China, which is also risky.

In-house Inspection Team. Hiring or creating a QC team within your company is also a perfect option to ensure accurate and unbiased results. It can be costly and unprofessional.

Third-Party Inspection Agency in China. You should hire a third-party inspection agency like Tetra-Inspection with years of experience in the Chinese manufacturing industry.

The success of your partnership will rely on effective communication. You can create a quality control checklist or inspection checklist.

What should you include in the Quality Control Checklist in China?

The quality control checklist for pre shipment inspection in china should be bilingual. Even though your inspection agency speaks English, you can include a translation in their first language to enhance clarity. You should include these five elements in your inspection checklist:

- Product requirementsPackaging specification like

- packaging materials and packing method

- Defect Classification – the AQL standards for major and minor defects.

- On-site Product Tests

- Labeling and marking like CC Mark of Quality

These elements should be specific and objective to guarantee the accuracy of the results. Crafting a comprehensive checklist will enable your inspection agency in China to follow the appropriate Quality Control Process for your product precisely to the letter.

Inspection and audit types in China Quality Control Process

To ensure your product meets the requirements and specifications, the inspection agency will conduct a step-by-step assessment known as the China quality control process. The process consists of several types of product inspection and supplier audits.

Quality control audits can help you partner with the right supplier in China and avoid the risk of non-compliance and quality issues. Here are the four most common types of audits in China:

This audit is conducted when searching for the right supplier in China. It is used to verify the authenticity of a potential supplier and can help you avoid scammers masquerading as Chinese suppliers.

This audit focuses on social practices in the workplace of potential suppliers and can dig up any unethical social practices like exploitative labor. It can help you avoid unethical suppliers in China and protect your reputation.

This audit focuses on the capability and capacity of a potential supplier. It ensures you partner with a supplier capable of delivering your requirements.

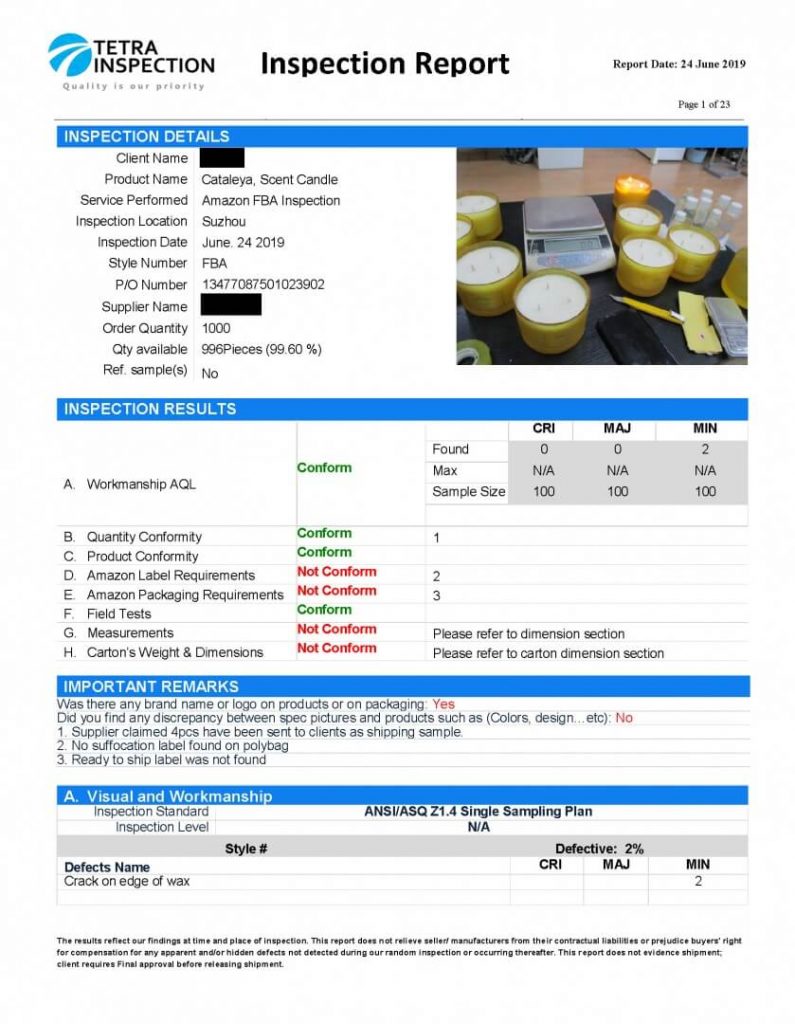

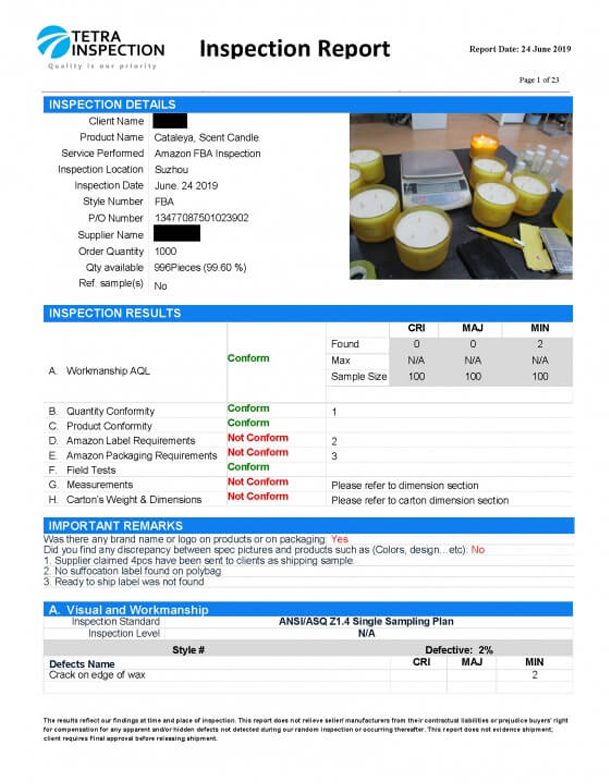

An example of specific audits is Amazon FBA, which helps Amazon sellers get the right supplier in China.

Whether you are a retailer or importer, these audits can mitigate risks and help you partner with the right supplier. You can enjoy all these benefits by hiring an experienced third-party inspection company like Tetra Inspection to audit potential suppliers for you in China.

- Initial Production Check (IPC) in China

- During Production Check (DUPRO) in China

- Pre-Shipment Inspection (PSI) in China

- Container Loading Check (CLC) in China

Initial Production Check includes several on-site inspections by third-party inspectors to assess your manufacturer’s production capacity, materials, and the implementation of the requirements. The inspections start before production begins to ensure the supplier can deliver an acceptable quality limit (AQL). It can last until 20% of production has been completed for First Article Inspection. The first items off the production line are inspected to correct any defects before mass production.

DUPRO, also known as On-Line Inspection, is an on-site product inspection in China conducted in the early stages of production when about 20% of the batch has been produced. It is undertaken to track quality and production progress. Importers engaging with suppliers from China can hire a QC expert to conduct DUPRO in the supplier’s factory to surface any defects before too many items are produced. DUPRO in China can help you reduce costly defects and quality issues in the early stages of the manufacturing process.

Pre-Shipment Inspection (PSI) is a systematic inspection of a sample selected randomly from all the batches already produced. It is conducted based on ISO standard sampling procedures to detect and solve any quality or conformity issues before the shipment. PSI is carried out near the end of production when at least 80% of the units in the order have been produced and ready for delivery.

Container Loading Check (CLC) is the final step in product inspection for imports from China and focuses on ensuring that only approved products are shipped. Your third-party QC inspector will check the accuracy of the total quantity and the number of products loaded in regards to sizes, color, and styles in shipments. The number of products loaded for shipments heading to different destination markets is checked. Any issues with the quantity loaded are addressed before shipment is delivered to you.

How to conduct a social audit in China

If you are planning on conducting a social audit in China, there are a few key things you need to keep in mind. First of all, it’s important to work with a qualified and experienced auditor who understands the Chinese regulatory environment and is experienced with the local business culture.

You should ensure that your company’s policies and procedures are up to date and in compliance with all relevant laws and regulations.

If violations are found during the audit, corrective action must be taken immediately. You should work with your auditor to develop a plan for fixing the violations and ensuring that they are corrected promptly. You should also keep track of all corrective actions taken so that you can provide documentation to your auditor upon request.

With the right preparation, a social compliance audit in China can help you ensure that your business is operating socially responsibly and in compliance with all relevant laws and regulations.

If you’re looking for a reliable social auditing firm in China, Tetra Inspection can help you. Our auditors are well-versed with social auditing standards and have years of experience conducting social audits in China. We’ll work with you to ensure that your company is in compliance with all relevant laws and regulations, and we’ll help you take corrective action if any violations are found. Contact us today to learn more about our social auditing services.

Tetra Inspection’s Quality Control in China

Tetra Inspection is specialized in product inspections for importers and retailers engaged with suppliers from China. Our Chinese team is stationed in Shenzhen, Dongguan, Guangzhou, Shanghai, Hangzhou, Ningbo, Chengdu, Tianjin, and throughout the Chinese territory. In China, our inspection team will ensure that your goods meet all regulations and requirements. We offer a wide range of quality control services in China, including:

Tetra Inspection’s Quality Control Services in China

- Supplier Audits in China

- Factory Audits (ISO9000) in China

- Social Audits (SA8000) in China

- Amazon FBA in China

- Pre-Shipment Inspection in China

- China Factory Inspection

Tetra Inspection Product Expertise in China

- Furniture Quality Control in China

- Toys Quality Control in China

- Footwear Quality Control in China

- Fabric Quality Control in China

- Textile and Garments Quality Control China

- Electronics Quality Control in China

- Bags Quality Control in China

Tetra Inspection’s highly experienced product inspectors in China can help you monitor, inspect, and test the quality of your product. Our product inspection services in China cover every stage of manufacturing. Tetra Inspection’s quality control in China includes Initial Production Check (IPC), During Production Inspection (DUPRO), Pre Shipment Inspection china (PSI), Loading Check (CLC), Production Monitoring (PM), and Pre-Customs Clearance Inspection (PEO).

With Tetra Inspection by your side, you can safeguard the quality of your product cost-effectively. We are renowned for transparent pricing in China with comprehensive inspection reports and certificates. Our standard inspection fee in China is $240 all-inclusive. To avoid quality issues, non-compliance, and costly delays, you need Tetra Inspection on your quality control in China and other Asian countries, please contact us.

Related Articles: https://tetrainspection.com/quality-blog